Evaluation

Final Major Project – Pattern

Hayley Young

When

I wrote my statement of intent at the beginning of the project, I aimed to

create a garment based on my experience in Marrakech using appropriate colours

and patterns. I wanted to use drapery as

an element as well as laser cutting and etching as an interesting way of using

pattern. As I started my project and tried to realise my ideas I came across a

few problems which made me change my mind and develop my ideas into something I

could work with.

I

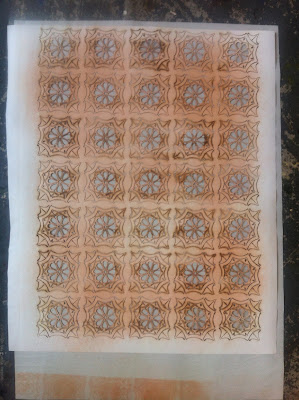

was certain I was going to use laser cutting to create my pattern on the final

garment so I developed the design on Illustrator and found a company where I

could laser cut. Once I got there and tried my pattern on the fabrics I had selected,

I realised laser cutting would not work in the way I wanted it to. But I

refused to waste the time and effort I had put into it and made an A2 laser cut

paper stencil of my design which was then used to heat transfer onto my silk

and create my light boxes. I also faced a few

problems with making my patterns and garments. I made my own patterns by

initially making paper toiles and then calico toiles, but I could not figure

out how to make the kind of hood I wanted. I finally managed after about 5

hours of making paper patterns. This was all to be tested again as I tried to

make the garments out of the proper fabric. It was so stringy, that every time

I cut a curve it all came apart. I then had to transfer my sewing machine to

the floor and literally sew centimetre by centimetre and use a scrim fabric as

backing to keep it together. This worked for the dress but the hood would not

be as good or neat I wanted as I could not keep it together.

When

looking back and thinking about what I could have improved on I think I should

have researched my fabric better and found out what would work with laser

cutting. I should have looked further into cutting techniques to try and stop

my fabric from falling apart. I think I did quite well with time management and

roughly stuck to my weekly plan, but I was delayed slightly due to the problems

that came up.

Even

though my detail Ideas changed I feel like I stuck to the basic plan within my

statement of intent and managed to create the look I was trying to get. I stuck

to my colour palette and the natural fabrics I wanted to use. I put a lot of

effort, time and thought into the details and tried my best to do as much as I

could independently. I would have been happier with the result if the stitching

and cutting were a bit neater and the laser cutting had worked, but I am happy

with my finished piece and am proud of what I have learned from the problems

and the experience as a whole.